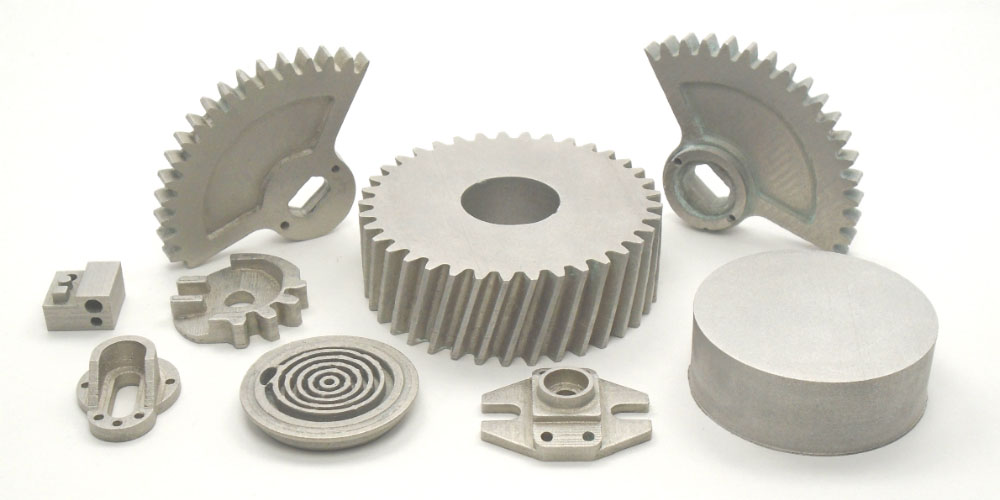

Depending on the product you wish to manufacture, developing prototypes is crucial. Prototypes are essential as it helps you to align consumer’s needs and specifications better. Thus, ensuring that all solutions and elements are pinned done is vital. Furthermore, the latest advancements in prototyping, such as the one found in Rapid Prototyping China, allow for the production of complex parts. Thus, there is no limit to the type of prototypes that can be produced. Additionally, different prototypes come at different prices. The different prices can be attributed to various factors. Therefore, this post aims to inform you of four factors that impact the cost of China prototype manufacturing.

4 factors that impact the cost of china prototype manufacturing

1. Tooling

The tools and machines used in the prototype manufacturing process play an essential role in pricing prototypes. For example, some manufacturing processes require fixed tools such as injection molding, urethane vacuum casting, or pressure die casting. Such tools’ cost basis may be; parts of the tool, any particular treatment they may require, such as hardening, and the materials used to make them. Furthermore, there are some processes like CNC machining that do not need fixed tooling. Therefore, procedures involved, if used for a small batch, may reduce the project’s cost.

2. Manufacturing process used

The manufacturing process used in developing a part depends on its application and specification. Thus, the manufacturing process selected directly impacts the cost of production. For example, if you wish for a plastic component manufactured. Then, different processes can be used, such as; compression molding, injection molding, and extrusion molding. Injection molding is more expensive than extrusion molding and compression molding.

But injection molding is best used for complex parts and needs the use of an injection tool. Thus, the manufacturing process used plays a significant role in the overall price of a project.

3. Labor used

The cost of labor is an essential element to consider when it comes to the pricing of your part. The more expensive the labor cost is, the more the overall production costs. The opposite is also true; the cheaper the labor cost is, the cheaper the overall production cost will be. For example, projects that need assembly work are labor-intensive. Thus, the expected final price will be higher.

Most businesses prefer overseas manufacturing because of the cheap cost of labor. In countries like China, the cost of labor is very reasonable. Thus, many companies opt to acquire China’s prototype manufacturing services.

4. Volume

The volume produced also plays a role in cost. The more parts are produced, the cheaper the overall project cost will be. The opposite is also true; the less the parts are produced, the more expensive the overall project cost will be. Thus, high-volume production is cheaper than low-volume production. Furthermore, production procedures are optimized as the manufacturing volumes increases, thus ensuring reduced waste and maximizing efficiency.

Conclusion

Many factors play a crucial role in determining the prototype manufacturing costs. Thus, if you wondered why different prototypes have different prices, then the above factors will help you answer that question.