The plastic injection molds market is awash with dozens of brands and retailers. The lack of strict barriers to entry into the market is good for customers when it comes to product differentiation. But it may also leave them vulnerable to unscrupulous buyers. Getting cheap knockoff molds that crack during cooling is easy. For high quality plastic injection molds, read this blog post.

The following guidelines will help you get value for your money when purchasing high-quality plastic injection molds in 2020:

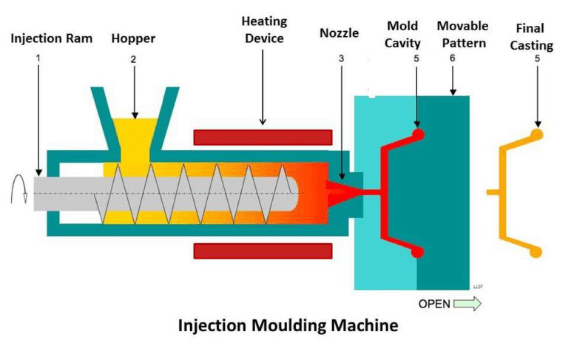

Product quality: Before spending your hard-earned money on a plastic injection molding machine, ensure that it produces high-quality final products. Machines with even distribution of mold surface, cavity, and injection temperatures will result in final products that have a glossy surface and no bends.

Uneven temperatures in these key areas can lead to the production of poor quality products that do not meet industry standards. Additionally, achieving brand consistency through uniform products will be considerably hampered. Always inquire from your seller about these critical design features to avoid production hitches, especially when you are looking to purchase a machine for an upcoming project.

Production speed and scalability: Purchasing a plastic injection molding machine is a costly venture. Therefore, its production capability, including speed and scalability, should match your needs and price tag. When shopping the machine, always check vital features such as cooling systems and cycle time, and overall production cycle.

These features have a direct bearing on whether your molding machine will withstand the demands of your productions. Ensure that the production capacity of the plastic injection molding machine is scalable to meet production demands. Scalability should also be considered within the context of the complexity of the mold patterns, colors, and final product sizes.

Price vs. budget: One of the most important factors to consider when shopping for a plastic injection mold is the price of the machine relative to your budget. A comprehensive budget should reflect your needs and financial situation.

Therefore, a final price estimate should have a price range that your company can pay. The price of the machine should fall within the price ranges set during budgeting. Avoid the temptation of impulsive buying and last-minute changes in priorities.

Repair and maintenance: A machine without readily available spare parts may end, costing you more in the long run. You might find yourself stuck with an expensive plastic injection mold that is nonfunctional because of difficulties in carrying out proper repair and maintenance practices. If possible, ask the retailer about the availability of spare parts and accessibility of maintenance services for the machine.

In some cases, the company may also specialize in the repair and maintenance services for their product. Production downtimes due to broken down machines can severely reduce the company’s bottom lines. Poorly maintained or damaged machines also lack the speed, precision, and accuracy needed for mass production of identical products.

Final Thoughts

A high-quality plastic injection molding machine that is fully functional, which significantly improves a company’s production capacity. When shopping for one, always work with a budget. And ensure that the machine will meet your needs.