Overmolding refers to a unique process used in injecting mold into products. Usually, it involves different activities aimed at seamlessly combining several materials into one part of a product. The entire process can also include rigid as well as plastic-based components usually overlaid using a thin yet pliable material such as rubber thermoplastic. In this article, we look at all elements of the overmolding process and its uses.

- Why Manufacturers Prefer Overmolding

Every manufacturer aspires to produce items at a slightly lower cost. For that reason, many have diverted their attention to seeking better production strategies such as overmolding. The method offers manufacturers the chance to product soft exteriors on their products. Other than that, overmolding will enhance the grip of your products in many ways.

- Overmolding Enhances The Style Of Your Commodities

Overmolding is a preferred manufacturing process when it comes to product creation. It offers you as the manufacturer with the opportunity to create a relatively enhanced-looking commodity. In the long run, you will have products with improved longevity too.

- Cost Of Production

Overmolding is slightly cheaper compared to other manufacturing processes. This implies that it is one of the most reliable methods of production. For that reason, several manufacturers prefer it to different manufacturing processes. Overmolding has a way of making your products look enhanced at a slightly lower cost compared to several other manufacturing processes in the industry.

- Enhanced Performance

As the name suggests, overmolding is slightly overbearing compared to the usual molding processes. This implies that the manufacturing process relies on your unique understanding of other professionals to become ideal. In this case, TPE is used as the primary raw material for production. It helps in crafting perfect material for different products. At the same time, overmolding is a reliable production method for different products.

- Multiple Material Molding

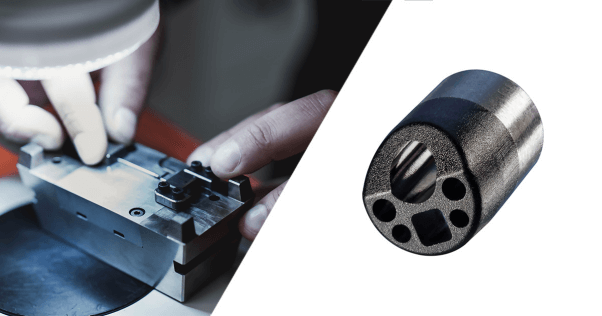

Overmolding enables you to reproduce your products. With that in place, you will be in a position to produce various products at once. The molding process needs a particular form of injection using a molding machine, which is often equipped with approximately two to more barrels. These devices will then be shot into the mold in the process of manufacturing your products. In the long run, you will be in a position to choose a multi-molding to reduce the cycle times required in the long term.

- Effects On Thickness

Overmolding has its benefits on the thickness of the end-products. In this case, it would mean that the products will be thicker than how they would be when it comes to other manufacturing processes. Overmolding is typically overbearing to the raw materials. Therefore, it is one way through which manufacturers can quickly thicken the walls of their products in the long run.

Take-Home

As a professional serving in the manufacturing sector, you need to understand the overbearing process of overmolding. As we have indicated in this article, it is the production of a substrate part using injection molding as a significant reference point.